Aluminium sheets are a versatile and essential material used across various industries and applications. From construction to transportation, and even DIY projects, their lightweight nature, durability, and corrosion resistance make them a top choice for many.

However, to truly make the most of aluminium sheets, it’s important to understand their properties, available options, and how best to utilise them.

Why Aluminium Sheets?

Aluminium is one of the most widely used metals in the world, and for good reason. It combines strength with a relatively light weight, making it ideal for structural applications. Aluminium sheets, in particular, are favoured for their ease of fabrication, resistance to rust and corrosion, and ability to be recycled, which adds to their appeal in environmentally conscious markets.

When you’re working with aluminium sheets, you’ll find that they are highly adaptable. Whether you need to shape, cut, or weld them, aluminium sheets offer flexibility while maintaining strength. Additionally, they can withstand harsh weather conditions, which makes them perfect for outdoor uses like roofing or cladding.

Understanding Aluminium Sheet Grades

Not all aluminium sheets are created equal. There are different grades available, each suited for specific purposes. Selecting the right grade is key to ensuring your project’s success. Here are a few common aluminium sheet grades and their uses:

- Grade 1100: This is considered pure aluminium, known for its excellent corrosion resistance and high thermal conductivity. It’s typically used in applications that require a high level of formability, such as chemical equipment and food packaging.

- Grade 3003: This grade offers excellent workability and moderate strength. It’s often found in roofing, gutters, and cookware. Its corrosion resistance also makes it suitable for marine environments.

- Grade 5052: Known for its strength and high fatigue resistance, this grade is used in applications like marine environments and aircraft fuel tanks. It also has excellent corrosion resistance, especially in saltwater conditions.

- Grade 6061: This is one of the most versatile aluminium grades, combining good mechanical properties with excellent weldability. It’s often used in structural applications, making it a popular choice in construction.

By selecting the right grade for your project, you ensure that the aluminium sheet performs well under the specific conditions it will face.

Thickness Matters

The thickness of aluminium sheets is another crucial factor to consider. Thicknesses can vary widely, from ultra-thin sheets (used in packaging) to thick plates (used in heavy-duty structural applications). Standard sheet thicknesses range from 0.5mm to 6mm, but for some specialised applications, thicker sheets may be necessary.

Thicker sheets are generally more durable and offer greater strength, making them ideal for heavy-duty uses like construction, shipbuilding, or transportation. Thinner sheets, on the other hand, are easier to work with and are commonly used in applications where flexibility and formability are required, such as in automotive panels or decorative features.

Before purchasing aluminium sheets, it’s essential to determine the appropriate thickness based on the demands of your project. For example, if you’re looking to use aluminium sheets for roofing, a thickness of around 1.2mm is often sufficient, but if you need sheets for structural support, you’ll likely require something thicker.

Making Aluminium Sheets Work for Your Project

To make the most of aluminium sheets, it’s important to think about how you’ll process and finish them. Here are some tips for getting the best results:

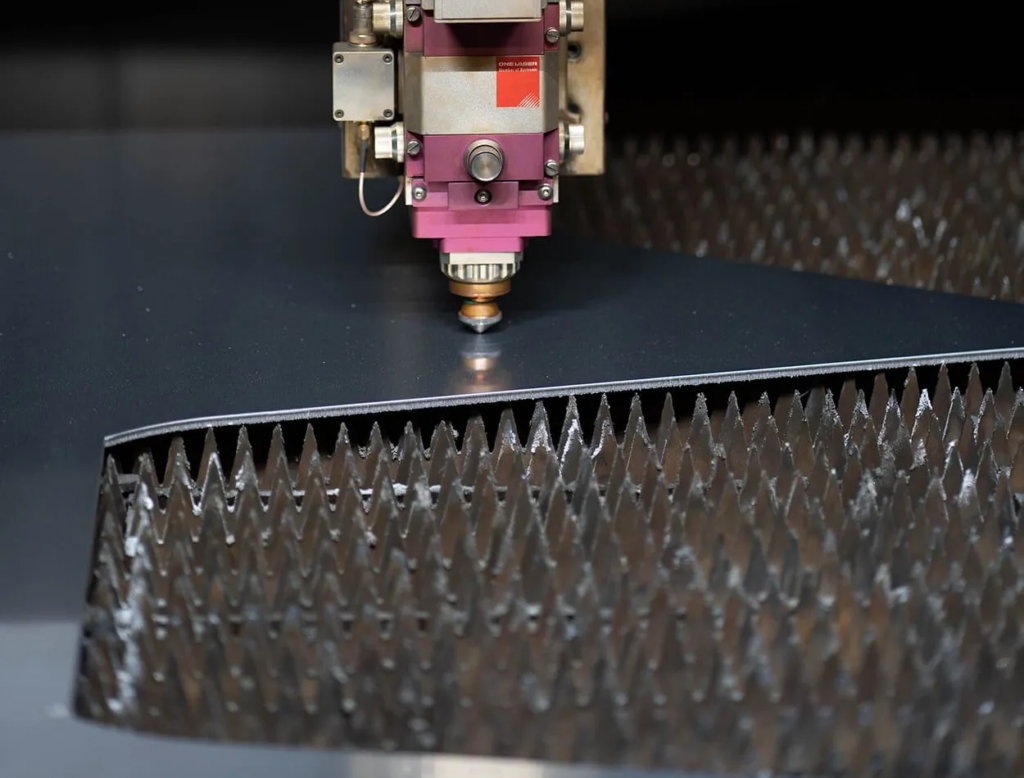

- Cutting: Aluminium sheets can be cut with a variety of tools, including tin snips for thin sheets or a table saw for thicker sheets. Always ensure you’re using the right tools for the thickness you’re working with to avoid damage to the material.

- Bending: Aluminium sheets are easy to bend, especially the thinner grades. However, the grade you’re working with will affect how much bending it can handle before cracking. For instance, Grade 5052 can handle more severe bends than some other grades.

- Welding: If you need to weld aluminium sheets, make sure to choose a grade that is weldable, such as 5052 or 6061. Ensure you’re using proper techniques, as aluminium can be more challenging to weld than steel due to its lower melting point.

- Finishing: To enhance the durability and appearance of aluminium sheets, you may want to apply a finish, such as anodising or powder coating. Anodising not only protects the metal from corrosion but can also improve its appearance by adding colour.

Common Applications of Aluminium Sheets

Aluminium sheets are used in a wide variety of applications, thanks to their flexibility and durability. Here are some of the most common uses:

- Construction: Aluminium sheets are often used in the building industry for roofing, cladding, and insulation. Their lightweight nature makes them easy to install, while their resistance to corrosion ensures longevity in harsh Australian climates.

- Automotive Industry: Due to its lightweight properties, aluminium sheets are used in the manufacture of car bodies, particularly in high-performance vehicles where weight reduction is a priority.

- Aerospace: The aerospace industry relies on aluminium for its combination of lightness and strength. Aluminium sheets are used in the production of aircraft bodies, wings, and other components that require both durability and minimal weight.

Household Items: Aluminium sheets are found in everyday products, from kitchen appliances to packaging materials. They are used in things like aluminium foil, cookware, and even some electronics.

Maximising Value: Recyclability and Sustainability

One of the biggest benefits of aluminium is its recyclability. Aluminium sheets can be recycled indefinitely without losing their quality. This makes them an environmentally friendly choice for businesses and individuals looking to reduce their carbon footprint.

By choosing aluminium sheets, you are not only benefiting from their practicality but also contributing to sustainability efforts. When your project is complete, recycling any leftover material ensures that it goes back into the manufacturing cycle, reducing the demand for new raw materials and lowering overall environmental impact.

Conclusion

Aluminium sheets are an invaluable material across industries, offering a balance of strength, flexibility, and sustainability. Whether you’re working on a large construction project or a smaller DIY task, understanding the grades, thicknesses, and processing techniques will help you make the most of this versatile material. By selecting the right type of aluminium sheet and using it efficiently, you can ensure that your project is both high-quality and cost-effective.