Drive through any Aussie suburb built in the last decade and you’ll spot a pattern: gates are no longer simple rectangles on hinges. Curved sliders, laser‑cut patterns, bi‑fold entries, and cantilevered statements now anchor frontages from Hobart to Cairns.

These designs look impressive, but they still need to open, close, and secure the property day in, day out. The metal making this possible—without turning maintenance into a full‑time job—is aluminium. Below, you’ll see exactly how aluminium supports complex gate ideas while keeping the practical bits rock‑solid.

The Push for Complex Gate Designs in Modern Australian Architecture

Homeowners and architects are demanding more from gates than ever before.

- Growing emphasis on curb appeal in competitive property markets

- Desire to integrate gate lines with mixed‑material façades—think brick, render, timber battens, and standing‑seam roofs

- Need for multi‑use entries that handle vehicles, cyclists, couriers, and pets with equal ease

- Tech‑driven expectations for automation, smart locks, and even solar power built straight in

- Council rules in bushfire and flood zones pushing designers toward specific clearances, airflow, and ember resistance without sacrificing style

These shifts steer projects toward intricate shapes, hidden hardware, and split‑function panels—all challenges that aluminium handles better than heavier, rust‑prone alternatives.

Aluminium’s Material Advantages for Complex Geometry

Form a curve, carve a pattern, or hide a motor—aluminium’s properties help you do it all.

- High strength‑to‑weight ratio supports large spans without giant counterweights or industrial‑sized motors

- Malleability allows tight bends and custom profiles without risking crack lines or warping

- Natural corrosion resistance keeps joints and decorative edges crisp, even in coastal environments

- Compatibility with powder coating and anodising means you can apply any colour or texture without closing tolerances or blurring laser‑cut detail

Because the base metal works so willingly, designers can chase daring concepts knowing the finished product will still perform reliably at the front gate for twenty‑plus years.

Lightweight Strength: Keeping Moving Parts Reliable

Complex motion needs components that aren’t fighting gravity every moment.

- Aluminium frames reduce hinge and motor load, extending service life and cutting maintenance visits

- Lighter leafs allow bi‑fold or telescopic gate arms to move quickly yet stop safely when sensors detect an obstacle

- Reduced weight enables trackless cantilever gates that glide over rough driveways without rails collecting leaves, sand, or flood debris

- Lower inertia means emergency‑stop functions in automation systems respond faster—important for family safety and compliance with Australian Standards

Put simply, aluminium lets you push design boundaries without oversizing every component underneath.

Extrusion Technology: Turning 3D Ideas into Real‑World Profiles

The extrusion press is the designer’s best mate.

- Custom channels hide wiring for keypads, LED strips, CCTV, or magnetic locks, so surfaces remain clean and vandal‑resistant

- Internal ribs boost rigidity at precise points, allowing micro‑thin edges elsewhere for that barely‑there aesthetic

- Interlocking tongues and grooves help assemble large gate panels on site with little welding, maintaining alignment and speeding up installation

- Integrated rainwater drains, gaskets, and brush seals slot directly into the profiles to keep mechanics dry and debris‑free

Because every millimetre of the profile can be engineered, aluminium delivers forms that would send fabricators scrambling if they were restricted to flat steel or timber boards.

Precision Fabrication for Seamless Functionality

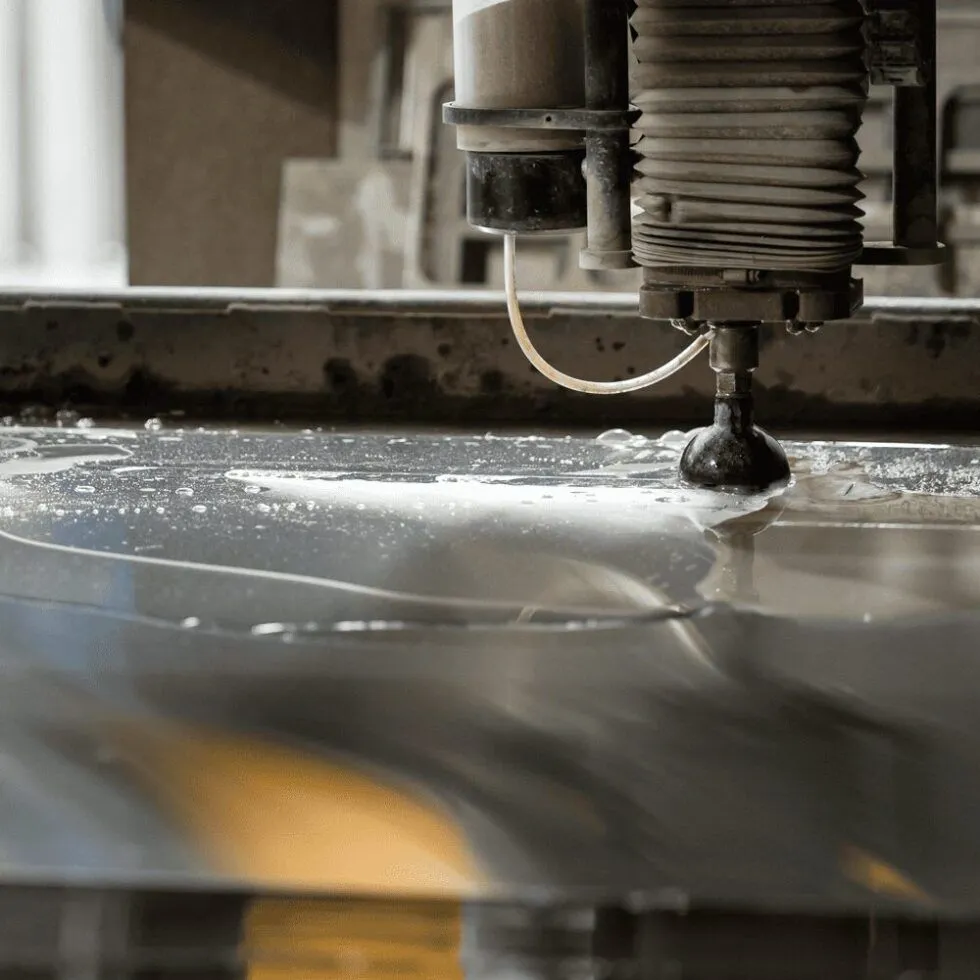

CNC routers, laser cutters, and TIG welders love aluminium.

- Laser‑cut patterns—geometric, botanical, or full‑blown artwork—turn privacy screens into statement pieces without adding extra weight

- CNC milling creates rebated pockets for hinges, strike plates, and smart‑lock housings, so nothing protrudes to catch clothes or fingers

- TIG welding fuses joints with minimal distortion, ensuring long panels stay perfectly straight—a must for sliding gates spanning five metres or more

- Power‑coat lines bake finishes at temperatures that bond the colour into the metal’s surface, safeguarding fine details from peeling or chalking

This precision keeps complex designs looking pristine and operating smoothly long after the builder’s warranty expires.

Design Ideas Made Possible by Aluminium

Below are real‑world concepts that thrive because aluminium makes them practical.

- Telescopic driveway gates that split into two or three overlapping panels to save run‑back space on short urban driveways

- Curved pivot gates swinging from a single vertical post, creating a dramatic reveal as the arc opens toward the street

- Louvre‑slat gates with adjustable blades allowing airflow and privacy control—handy for pool pumps or bin enclosures next to the main drive

- Laser‑cut silhouette gates featuring custom family crests, indigenous patterns, or coastal motifs that cast shadow art across the entry path

- Bi‑fold vehicle/pedestrian combos where one leaf swings for deliveries while the rest slides aside for the ute

- Vertical lift gates rising like a shopfront shutter, popular on steep blocks where swinging or sliding isn’t viable

Try those in hardwood and you’ll fight swelling, bowing, and weight. Build them in mild steel and you’ll be chasing rust bubbles in less than two summers. Aluminium shrugs off both issues.

Final Verdict: Form and Function in One Aluminium Package

Aluminium has changed the gate game for Australian designers, builders, and homeowners. Its unique blend of lightweight strength, corrosion resistance, and near‑unlimited extrusion options means you can:

- Sketch ambitious shapes—from sweeping arcs to tight laser‑cut mosaics—knowing they’ll build true.

- Integrate automation and smart tech seamlessly, without giant motors or ugly bolt‑ons undermining your design intent.

- Trust the gate to stay smooth, straight, and secure through cyclones, salt spray, and scorching UV—with basic garden‑hose upkeep.

Complex gate design no longer needs to trade off practicality or longevity. With aluminium, you can have your architectural centrepiece and use it every morning without a hitch. If bold frontage design and reliable everyday function sit atop your wish list, aluminium is the material that turns both into reality—beautifully and sustainably.