Heating keeps your home comfortable, but it also sits among the highest ongoing costs through winter. Skipping maintenance may feel like saving money in the short term, yet the bill arrives in other ways. Energy waste, emergency callout fees, premature part failures, and even voided warranties compound into a far bigger spend than a simple pre-season service.

Let’s breaks down where the money leaks out, how to quantify the risk, and the practical steps that keep costs predictable. The constant theme is simple. Plan ahead and use a licensed technician to tune, test, and document your system before the cold arrives.

The Hidden Cost Curve of Neglect

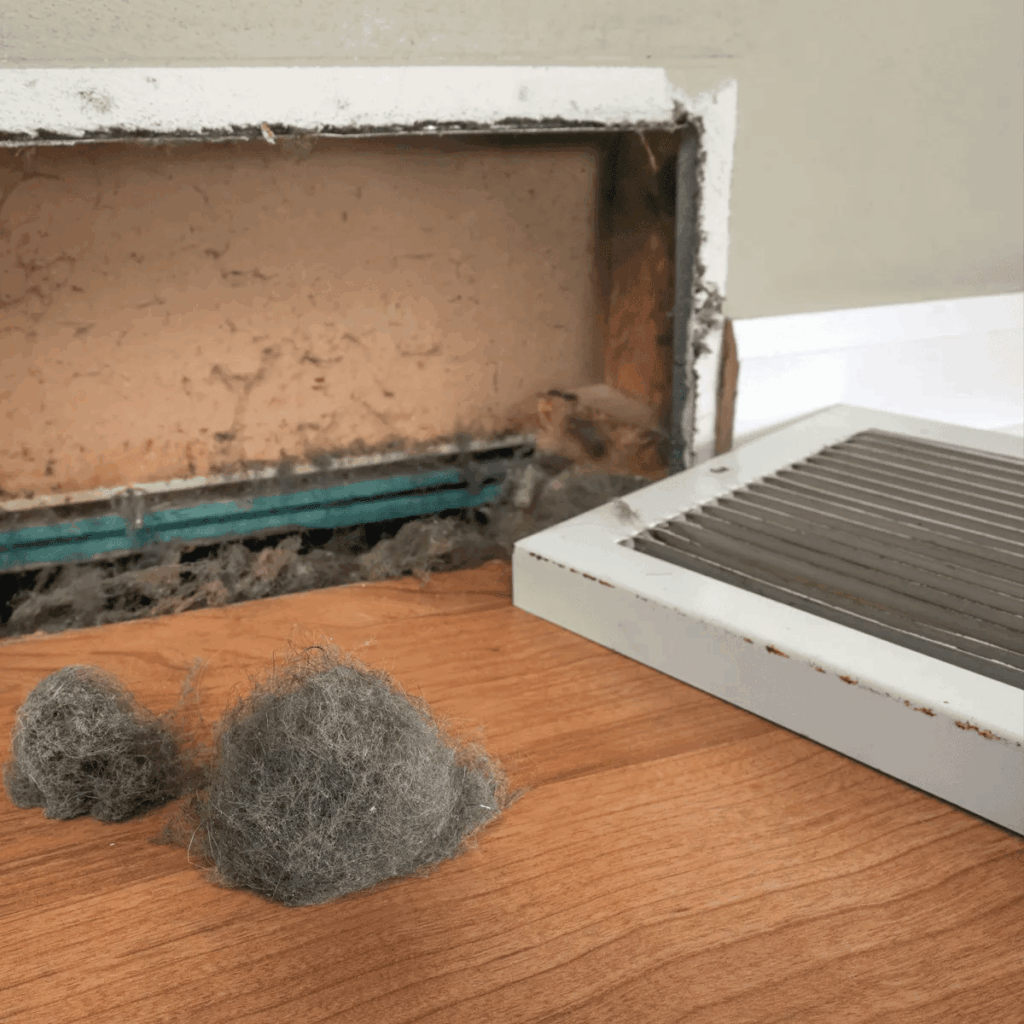

Heaters do not fail overnight. Performance drifts first. Filters clog, burners foul, bearings wear, and controls lose calibration. Each small issue nudges run time higher and forces components to work harder. The result is a curve where costs rise slowly, then sharply. Households feel it as a creeping energy bill followed by a mid-winter repair that requires special parts, overtime rates, or both. Attacking small faults early flattens that curve and protects the budget.

Energy Waste: How a Dirty System Burns Cash

Energy is the most obvious expense that increases when maintenance is ignored. Airflow restrictions, poor combustion, and incorrect refrigerant or control settings push run times up and starve rooms of heat. Even modest losses in efficiency translate directly into higher bills.

Common drivers of energy waste include:

- Clogged return filters that reduce airflow and force longer cycles.

- Dust on indoor and outdoor coils that lowers heat transfer.

- Burner fouling that weakens flame quality and wastes gas.

- Thermostat drift that overshoots or undershoots setpoint.

- Duct leaks that pour heated air into roof spaces.

Each item seems minor on its own, but together they can add a large percentage to winter energy use. A licensed technician will restore airflow, verify combustion, seal small duct defects, and recalibrate controls so the system reaches temperature faster and switches off sooner.

Emergency Repairs: Paying The Peak Price

When heaters fail on the coldest week, everyone calls at once. That timing drives up the cost of labour and parts, and it locks you into whatever slot is available. Emergency callouts, after-hours surcharges, and rush freight on components are all more expensive than a scheduled fix in autumn. The difference is not just money. It is also time without heating while waiting for the next available appointment.

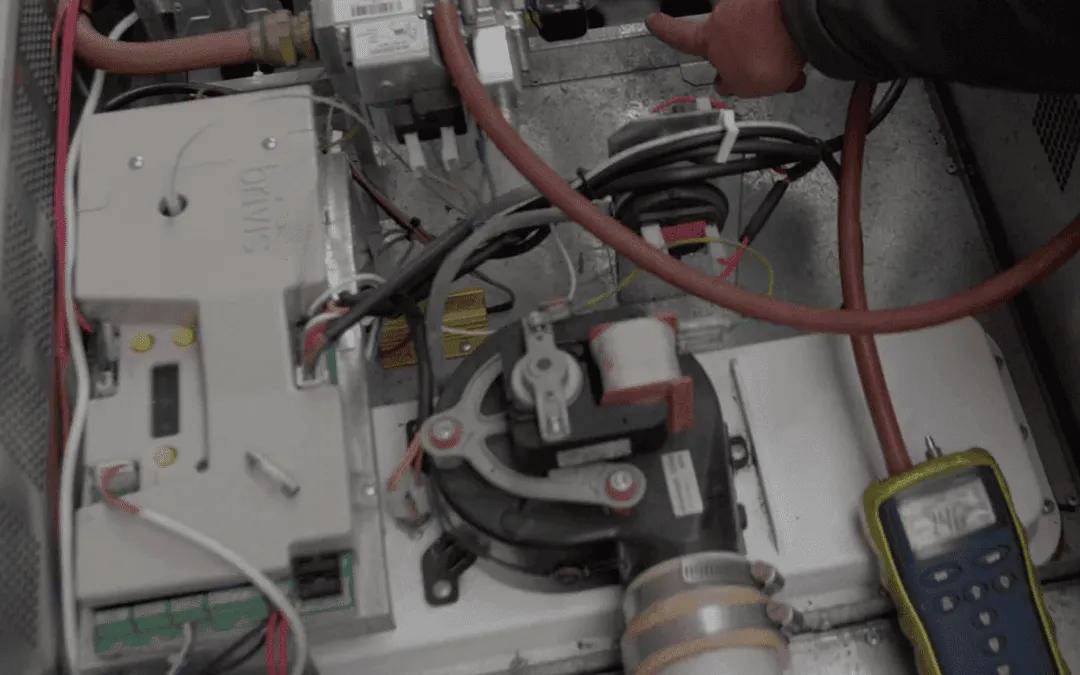

A planned service shifts spend to a controlled window. If a motor is drawing excess current or a flame sensor is deteriorating, you find out before winter. Replacing these parts during normal hours avoids the premium and protects the rest of the system from knock-on damage.

Premature Component Failure: The Compounding Effect

Running a system out of tune accelerates wear. Motors overheat, capacitors strain, igniters misfire, and heat exchangers experience thermal stress. A single weak link puts load on the rest of the chain. For example, poor airflow forces the unit to run longer, which heats electrical components for more hours, which shortens their life. A short, inexpensive service can prevent a long, expensive replacement later.

Signals that wear is compounding include noisy start-ups, intermittent cut-outs, short cycling, and rising energy use for similar comfort. Treat these as financial red flags rather than quirks. A licensed technician will measure motor currents, check capacitor health, and assess burner and heat exchanger condition so the system is not chewing through its remaining life.

Warranty And Insurance: How Documentation Saves Money

Manufacturers often expect regular servicing to keep warranty protection intact. Insurers may review claim histories and maintenance records when investigating fire, smoke, or carbon monoxide incidents. If your system has no documented service history, you carry more risk of out-of-pocket costs. The answer is simple. Keep dated service invoices and test results. Choose a licensed technician who records combustion readings, electrical measurements, and any repair recommendations. Those records can be the difference between a covered claim and an expensive lesson.

Downtime Costs: The Price of Being Cold

There is also a cost to comfort and productivity. Households lose sleep during cold snaps when heat fails, and small businesses lose revenue if a shop or clinic becomes uncomfortable for customers. Replacement heaters arranged at short notice are rarely the best value. They are the models in stock that week at the price you can secure. Planning maintenance and, if necessary, planning a replacement in the off-season gives you choice, better pricing, and time to compare efficiency ratings.

Health And Safety: Costs You Never Want to Pay

Neglected gas appliances can produce carbon monoxide if burners are dirty or heat exchangers cracked. Even without CO, poor combustion worsens indoor air quality, and dust accumulations around elements raise fire risk. Besides medical costs and potential property damage, there is the disruption of temporary accommodation and the stress of investigations. A pre-winter safety test is inexpensive compared to these outcomes. A licensed technician will verify flue draw, check burners, and test for CO at registers and around the appliance, then provide numbers that prove safe operation.

Rental And Strata: Financial Exposure for Owners and Managers

For landlords and strata managers, the financial exposure multiplies. Emergency callouts across multiple units, tenant compensation for prolonged outages, and reputational damage all add up. A simple calendar connecting pre-winter services to service reports and CO monitoring results reduces callouts and helps with insurance and compliance. Using a licensed technician standardises quality so each property is maintained to the same documented standard.

DIY Limits: Where Saving Money Costs More

There are safe tasks you can handle yourself, like replacing return filters, clearing leaves from outdoor units, and keeping supply registers open. The line you should not cross is anything involving gas tuning, electrical internals, flues, or refrigerant circuits. Guessing here leads to misdiagnoses that cost more later. The value of a licensed technician is in correct testing and root-cause fixes. They measure, interpret, and document, which avoids serial part swapping and repeat visits.

Scenario Modelling: Planned Maintenance Versus Reactive Repairs

It helps to think in scenarios rather than single events.

- Planned maintenance path – Early autumn service finds a weak capacitor and a dirty burner. Parts are replaced during business hours. Airflow and combustion are reset. Energy bills track level through winter. No emergency callouts.

- Reactive repair path – No service is booked. The unit runs long cycles with poor airflow and fouled combustion. Energy bills rise. On the first cold week, the igniter and board fail after repeated misfires. An after-hours callout, premium parts pricing, and rush freight are required. Two days without heat and a much larger total cost.

The difference between these paths often exceeds the price of two years of routine servicing.

Replacement Timing: When Spending Now Saves a Lot Later

Few costs exceed a rushed winter replacement. You may face limited stock, higher installation rates, and minimal time to compare efficiency or zone options. If your licensed technician advises that a heater is near end of life, use the off-season to plan a replacement. Off-season scheduling unlocks better pricing, cleaner duct or flue works, and time to improve zoning or insulation. The long-term savings on energy can be substantial, and you avoid the stress of a mid-winter changeover.

The Bottom Line: Maintenance Protects Your Money

Skipping winter heating maintenance looks like a saving but behaves like a debt that comes due in the cold. Energy waste accumulates quietly, emergency repair rates bite hard, warranties can fail to protect you, and wear compounds across every component.