When it comes to interior design, striking the right balance between form and function is key. That’s especially true when designing cabinets and storage solutions. In recent years, aluminium extrusion has become a go-to material for indoor cabinetry, storage frames, shelving systems, and even sleek architectural details.

It’s not just about good looks — aluminium extrusions offer durability, flexibility, and ease of use that other materials can’t always match.

Think About the Purpose of the Space

Before selecting aluminium extrusion for your cabinetry or storage, ask yourself what the space is being used for. The needs of a residential laundry are very different from those of an office archive room or a hospitality setting.

- Residential settings might prioritise clean lines, integrated finishes, and compatibility with timber or panel fronts.

- Commercial spaces may need more open-style shelving using aluminium frameworks that are adjustable and scalable.

- Workshops or garages benefit from tough, load-bearing shelving with extrusion frames that can support weight while resisting damage.

Understanding the demands of the environment will help you choose the right profile and finish, and ensure the final design suits both aesthetics and function.

Choosing the Right Aluminium Extrusion Profile

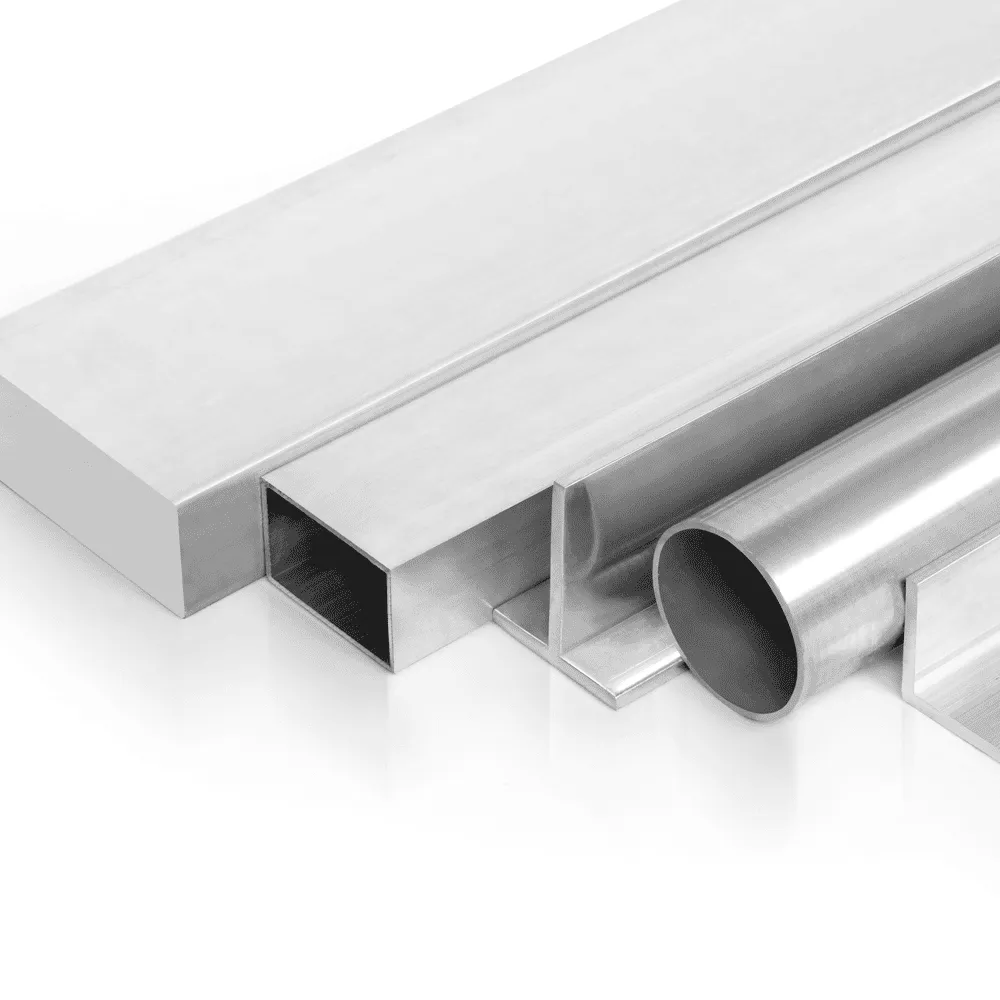

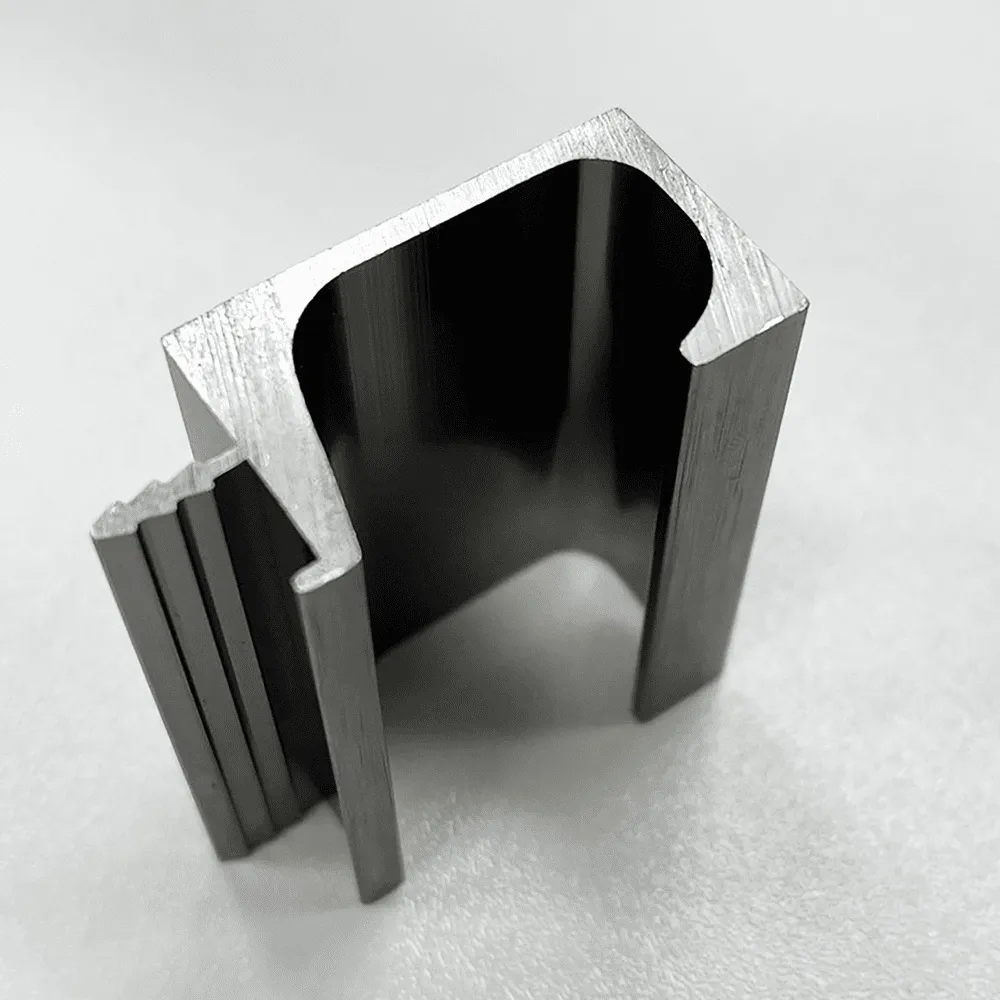

There’s a wide range of aluminium extrusion products available on the market, from simple angles and channels to more advanced structural profiles with built-in joining systems. Some common profiles for cabinetry and storage include:

- T-slot profiles – perfect for modular cabinet frames or shelving units where components need to be adjustable.

- Flat bars and angles – useful for reinforcing or trimming internal cabinetry structures.

- Box sections – offer clean lines and great strength for frame construction.

- Corner connectors and brackets – simplify the assembly process and help maintain square joins.

Think about not just how the profiles look, but how they’ll fit together, support the load, and interact with other materials like melamine panels or glass doors.

Consider the Finish

One of aluminium extrusion’s strengths is the variety of finishes available. From natural mill finish to powder coating or anodising, there’s an option to suit just about any interior style.

- Anodised aluminium offers a sleek, modern look and extra corrosion protection. It’s popular in kitchens, laundries, and bathrooms.

- Powder-coated finishes give you the flexibility to match almost any colour scheme, ideal for interior designers wanting custom tones.

- Brushed or polished finishes are often used in high-end fit-outs where visual impact is important.

Make sure your chosen finish complements the materials around it — whether it’s matching matte black cabinetry, blending with white shelves, or contrasting with timber accents.

Integrating with Other Materials

Aluminium extrusion works best when it’s part of a mixed-material design. One of the reasons it’s become so popular in cabinetry and storage systems is its ability to blend seamlessly with:

- Timber or veneer panels – creating a warm yet structured look

- Acrylic or glass – ideal for modern or display-style storage

- Melamine or laminate boards – practical for office or utility room cabinetry

- Wire or mesh – great for open storage or ventilation-heavy areas

Because extrusion profiles are available in so many shapes and sizes, they can be used as framing, edging, support structures or purely decorative trim.

Planning for Assembly and Installation

Ease of installation is one of the benefits of using aluminium extrusion, but planning still matters. Most profiles are designed to be joined with internal brackets, corner connectors, or self-tapping screws. For a more seamless look, some systems use concealed fasteners or slot-together joints.

When designing your cabinetry or shelving layout, think about:

- Access to fixing points

- Clearance for tools and hardware

- Modularity — will it need to be reconfigured later?

- Load-bearing capacity

- Mounting options — wall-mounted, freestanding, or fixed to floor/ceiling

Design with assembly in mind from the start and you’ll save time, money and headaches down the track.

Custom or Off-the-Shelf?

Another key decision is whether to go for pre-made extrusion systems or create something custom.

- Off-the-shelf kits are ideal for DIYers or small commercial projects where time and budget are limited. These often come with all the necessary fittings and instructions.

- Custom aluminium extrusion solutions are better for larger or more complex installations, where precise measurements, unique profiles, or specialised finishes are required.

Some local suppliers in Australia offer custom cutting, drilling, and finishing, so it’s worth speaking with them about what’s possible for your interior design project.

Sustainability Considerations

Aluminium is one of the most sustainable metals on the market — it’s 100% recyclable, doesn’t degrade over time, and often includes a high percentage of recycled content. Using aluminium extrusion for indoor storage is a smart move if you’re designing for sustainability.

Consider:

- Using local suppliers to cut down on transport emissions

- Choosing finishes that don’t off-gas or emit VOCs

- Designing modular or reconfigurable systems that can be reused in future fit-outs

Not only will this help the environment, but it can also add value to commercial projects where green building certifications are a priority.

Final Thoughts

Aluminium extrusion brings together the practical and the stylish, making it an ideal choice for indoor storage and cabinet systems. It offers versatility, strength, and a wide range of finishes that blend with modern design trends. Whether you’re a cabinet maker, interior designer, architect, or DIY renovator, using aluminium extrusion can simplify your project while delivering a high-end look.