In the age of climate change and environmental degradation, the push for sustainable materials has never been more critical. As governments, businesses, and individuals in Australia seek greener alternatives, aluminium extrusions present an opportunity for the environmentally conscious.

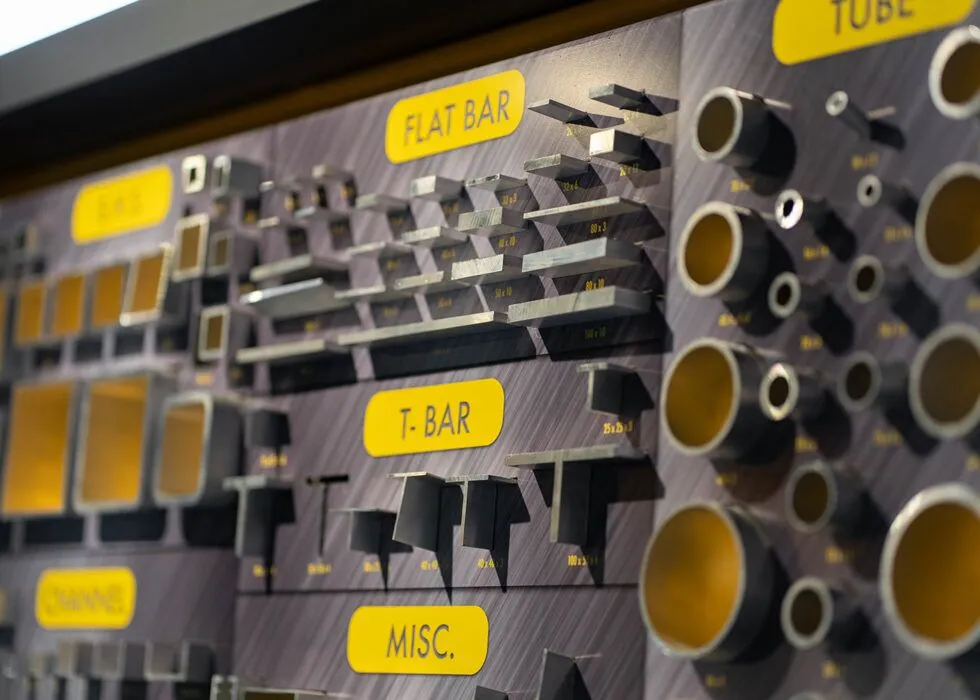

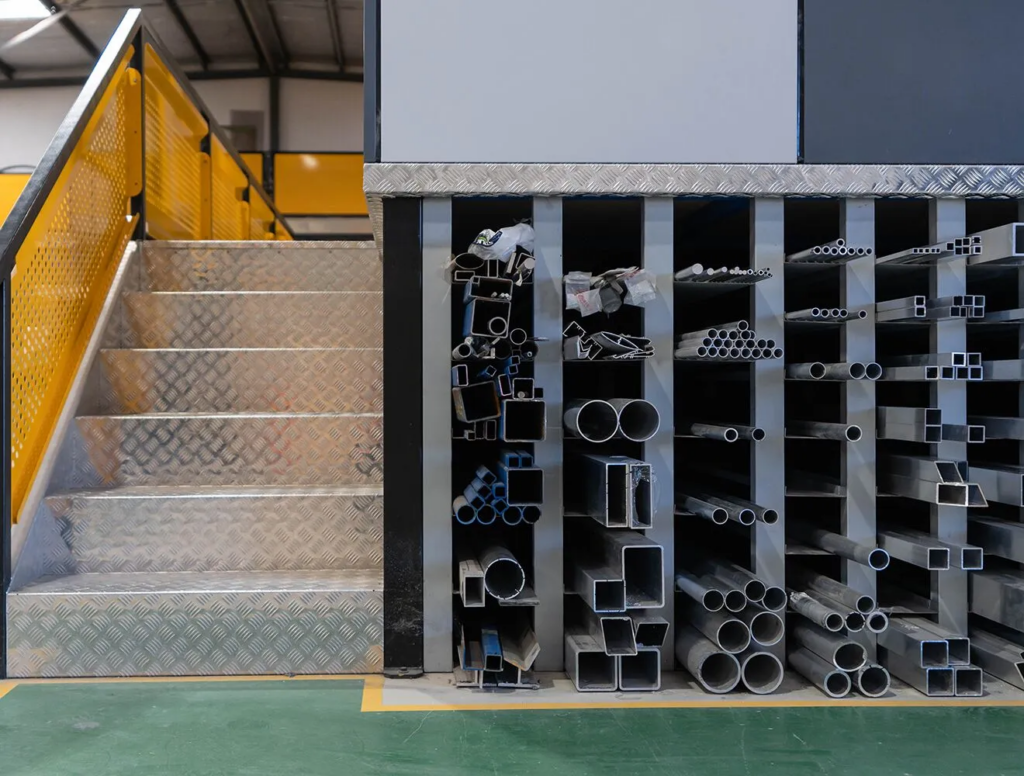

Aluminium extrusions are versatile and offer various benefits, from reducing carbon emissions to promoting recycling. For those passionate about sustainability, understanding the advantages of aluminium could be a game-changer.

Sustainability and Aluminium: A Perfect Match

One of the main reasons aluminium extrusions are gaining traction among environmentalists is their sustainability. The aluminium industry has taken steps to minimise its environmental impact, and aluminium as a material is inherently more eco-friendly compared to many other metals.

Recyclability of Aluminium

Aluminium is 100% recyclable without losing any of its quality during the recycling process. This characteristic gives it a major advantage over other materials. Recycling aluminium requires only 5% of the energy used to produce it from raw materials. In Australia, where the demand for aluminium continues to grow, this energy-saving benefit is vital in reducing the overall carbon footprint of the industry.

Additionally, the recycling process significantly reduces the emission of greenhouse gases. According to the Australian Aluminium Council, aluminium recycling saves over 90 million tonnes of CO2 annually worldwide. In a country like Australia, where environmental issues like global warming and resource depletion are at the forefront of public discourse, choosing aluminium helps address these challenges in a meaningful way.

Durability and Longevity

Another key advantage of aluminium extrusions is their durability. Aluminium doesn’t rust, and its resistance to weathering makes it an ideal material for products exposed to the elements. This means that aluminium extrusions often have a longer lifespan compared to materials like steel or wood.

A longer product life results in less frequent replacements, reducing waste and the demand for additional resources. This is particularly important in industries like construction, where materials need to stand the test of time in harsh conditions.

Aluminium Extrusions and Renewable Energy

Aluminium extrusions also play a significant role in the renewable energy sector. With the shift towards solar, wind, and other renewable energy sources, aluminium has become an essential component in the design and manufacture of energy-efficient systems.

Solar Panel Frames

Solar energy has become a crucial part of Australia’s renewable energy strategy. Aluminium extrusions are commonly used in the construction of solar panel frames because of their lightweight nature, corrosion resistance, and strength. The lighter the frame, the easier it is to install and transport, reducing the energy required for these tasks.

Furthermore, the durability of aluminium means that solar panel frames will last longer, even in harsh Australian climates, without needing to be replaced. This contributes to the overall sustainability of solar energy solutions, as less frequent replacement means fewer resources are consumed over time.

Wind Turbine Components

The renewable energy sector also relies heavily on aluminium extrusions for wind turbines. Components such as the nacelle, rotor hubs, and tower are often made using aluminium extrusions. The lightweight nature of aluminium reduces the overall weight of the turbine, allowing for more efficient energy generation.

As Australia moves towards a more sustainable energy mix, aluminium’s role in facilitating the development and implementation of renewable energy projects cannot be understated. Environmentalists seeking to support the growth of renewables should take note of aluminium’s contribution to these essential technologies.

Reducing Carbon Emissions in Production

While aluminium is already recognised for its recyclability, efforts are being made to further reduce emissions during the production process. Aluminium smelting, traditionally an energy-intensive process, has seen advancements in recent years. The introduction of renewable energy sources into aluminium production has been a game-changer.

Aluminium Extrusions in Construction: A Sustainable Choice

The construction industry is one of the largest consumers of raw materials globally, and as such, it has a huge impact on the environment. However, the use of aluminium extrusions in construction offers an opportunity to reduce this impact. The benefits of aluminium in construction are multi-fold, making it a viable option for environmentally conscious builders and architects.

Energy-Efficient Buildings

One of the most exciting applications of aluminium extrusions in construction is in energy-efficient buildings. Aluminium is commonly used in the fabrication of window frames, doors, and curtain walls, all of which can help improve the energy efficiency of a building.

Aluminium frames can support the use of double or triple glazing, which helps insulate buildings and reduce the amount of energy needed for heating and cooling. Given that Australia’s climate varies significantly from region to region, materials that aid in energy conservation are highly valuable. Using aluminium in construction contributes to a reduction in a building’s overall energy consumption, which is a major win for the environment.

Conclusion: Aluminium Extrusions for a Greener Future

For environmentalists in Australia, aluminium extrusions offer a wealth of benefits that align with sustainable goals. From recyclability and energy efficiency to the role aluminium plays in renewable energy and construction, this material is a valuable asset in the fight against climate change. As the demand for greener alternatives continues to grow, aluminium extrusions should be at the forefront of the conversation.