Network infrastructure keeps getting smarter, faster and more connected. Mobile data use keeps rising, more services move into the cloud and critical systems now live at the edge of the network instead of in one big central data centre.

All of that has one simple consequence. The rooms, shelters and buildings that house your network equipment cannot afford temperature swings, stale air or unplanned downtime. If the network is smart, the HVAC has to be smart as well.

This is where controls and remote monitoring move from “nice to have” to non negotiable. They sit at the centre of a modern HVAC upgrade for any critical comms or IT site.

Why Network Sites Need Smarter HVAC

Network and communications sites are not normal offices. They run 24 hours a day, they have dense heat loads and they are often in locations that are expensive or slow to reach.

That creates a few challenges:

- Equipment is sensitive to heat and humidity.

- Power use is high and energy costs add up quickly.

- Some sites are in regional or remote areas.

- You may be responsible for dozens or hundreds of locations.

In that context, a “set and forget” thermostat on the wall is not enough. You need HVAC systems that can hold tight conditions, recover quickly from faults and give your operations team clear visibility of what is happening.

Smarter HVAC controls and remote monitoring let you do that consistently rather than relying on luck and local staff.

From Thermostats to Smart Control Systems

For many older network sites, HVAC control is basic. A split system or package unit turns on when the room is hot and off when it cools down. Local staff might tweak the setpoint when they are uncomfortable or when alarms start ringing.

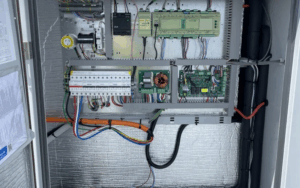

A modern control system is more deliberate. Instead of a single local thermostat, you have:

- Dedicated control panels for HVAC plant.

- Sensors for temperature, humidity and sometimes pressure or air quality.

- Programmable logic or dedicated controllers to manage how plant responds.

- Integration into a site controller, BMS or network operations platform.

This creates a foundation for proper control strategies. Duty and standby units can rotate fairly, redundancy can be managed, alarms can be consistent and you have a single source of truth for how the system is performing.

When you plan your next HVAC upgrade, the move from simple thermostats to a smart control approach should be a core part of the conversation.

Remote Monitoring: Seeing Every Room from Anywhere

Once you have solid local controls, the next step is remote monitoring. This is what lets your team see the state of each site without driving for hours or waiting for someone to call.

At a basic level, remote monitoring should give you:

- Live room conditions such as temperature and humidity.

- Status of each unit or plant item, including run and fault signals.

- Alarms for out of range conditions or equipment faults.

- Simple trends so you can see how conditions change over time.

For more advanced setups, remote monitoring can feed into a central dashboard that covers:

- All sites in a region, filtered by alarm state.

- Key performance indicators such as runtime, starts and energy use.

- Historical trends to help spot slow developing problems.

This is especially useful for regional exchanges, remote shelters and edge data sites where access is limited. Instead of waiting for IT alarms that say equipment is already hot, you can see the room conditions and HVAC performance in advance.

Data, Alarms and Actionable Insights

Smart controls and remote monitoring generate a lot of data. The goal is not to drown your team in charts. It is to turn that data into a few clear signals that help you act before issues become outages.

Useful patterns include:

- A room that consistently runs hotter than others.

- A unit that trips on fault every few days.

- A sudden change in runtime patterns after a setpoint or schedule change.

- Gradual drift in temperature or humidity that points to failing components.

To get that value, your alarm and trend strategy needs some thought. Good practice includes:

- Setting sensible alarm thresholds so you are warned early without constant nuisance alarms.

- Grouping alarms by severity so true risks stand out.

- Logging events in a way that lets you filter by site, unit or period.

When you combine good controls with smart alarm rules, you gain the ability to move from reactive callouts to proactive maintenance. That shift is one of the biggest advantages of tying controls and monitoring into an HVAC upgrade.

How Controls Fit into Your Next HVAC Upgrade

When people think about an HVAC upgrade, they often picture new units, new ductwork or new chillers. Controls and remote monitoring are just as important.

In many cases, the biggest improvements in performance and reliability come from:

- Smarter sequencing of existing plant.

- Better zoning and setpoint strategies.

- Improved monitoring and alarm logic.

That means you do not want to bolt controls on at the end. Instead:

- Include control strategy in the early design conversations.

- Make sure electrical, mechanical and controls people are aligned.

- Confirm that your remote monitoring requirements are part of the scope.

If you treat controls as a core workstream within the HVAC upgrade, you can avoid awkward compromises like new plant squeezed into old control panels, limited data points or partial integration that never quite works.

Smarter HVAC To Match Smarter Networks

As networks become more complex and more critical, the rooms and buildings that support them have to keep up. HVAC is a big part of that, and controls and remote monitoring are where the real intelligence sits.