A proper electrical safety audit is more than a once-over with a clipboard. It is a structured, evidence-based review of your site’s electrical systems that identifies hazards, verifies compliance, and maps out practical fixes in the right order.

Whether you manage a strata building, a retail complex, a warehouse, or a mixed-use facility, a well-run audit reduces risk, cuts unplanned downtime, and gives you a clear plan that your facilities team and trusted electrical services provider can act on.

Why An Electrical Safety Audit Matters

Before getting into the nuts and bolts, it helps to understand the role an audit plays in your wider safety and compliance strategy. Electrical faults are among the most common triggers for fires, equipment damage, and business interruption. They are also a key source of injury when protective devices are missing or not maintained.

A professional audit acts as a pressure test on your systems. It confirms that the right protection is in place, verifies that previous works meet current standards, and highlights where simple maintenance could prevent costly failures.

What A Professional Audit Covers

A credible audit looks end-to-end. It checks paperwork, inspects physical assets, and tests protection. The scope is tailored to site size and use, but typically includes the following.

- Documentation and single-line diagrams – An auditor verifies that as-built drawings match reality. Missing or outdated schematics are flagged, since they slow response during faults and hamper safe isolation.

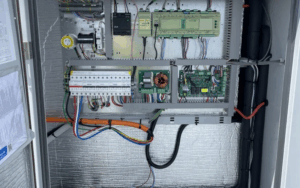

- Main switchboards and distribution boards – The audit inspects clearances, labelling, IP ratings, cable terminations, segregation, and condition of busbars and circuit protection. Signs of heat, corrosion, or water ingress are noted.

- Residual current devices (RCDs) and circuit protection – RCD trip times and test results are sampled to prove personal protection. Coordination and discrimination are reviewed, so a minor fault does not drop an entire tenancy.

- Earthing and bonding – The integrity of earthing systems and equipotential bonding is checked. Poor bonding is a common root cause of nuisance tripping and shock risk.

- Emergency and exit lighting – Function tests and logbook reviews confirm that egress lighting meets requirements and that discharge tests are up to date.

- Thermal imaging – Under normal load, thermography identifies hot spots at switchboards, connections, and MCCs. The audit correlates images to switchboard schedules to pinpoint the faulted element.

- Portable appliances and test-and-tag programs – Sampling verifies that tagging intervals and records align with site risk categories.

- Fixed plant and critical systems – Lifts, fire pumps, HVAC, refrigeration, and data equipment are reviewed to ensure supply reliability and emergency power provisions are suitable.

- Generators, UPS, and changeover controls – Load testing records, fuel quality controls, and maintenance logs are checked for reliability during outages.

- Solar PV, EV chargers, and modern loads – Newer assets introduce harmonics and backfeed considerations. The audit ensures protection and metering suit these technologies.

How The Audit Process Runs

A professional audit follows a repeatable process so findings are defensible and useful. The steps below outline what you can expect.

- Kick-off and information request – The auditor requests drawings, previous inspection reports, switchboard schedules, RCD logs, and maintenance records. This shapes the site plan and keeps time onsite efficient.

- Site walk and risk scan – A guided walk identifies obvious hazards, access constraints, and areas that require after-hours inspection. Tenant impacts are planned early to minimise disruption.

- Sampling and testing – The auditor uses risk-based sampling. Critical boards, high-load feeders, and problem areas are prioritised. RCD push-button tests and selective instrumented tests verify performance. Thermal imaging is performed under load where safe.

- Interviews and operational checks – Facility managers and contractors are asked about nuisance trips, hot smells, or past failures. This qualitative input often points to the real risk drivers.

- Evidence capture – Photos, thermal scans, and annotated diagram markups are gathered for each finding. Every recommendation is tied to a piece of evidence.

- Debrief and immediate actions – High-risk issues that could cause harm or significant downtime are raised in the debrief so you can act straight away with your electrical services provider.

What A High-Quality Audit Report Includes

The value of an audit is in the report you can use. Look for the following inclusions, as they make the difference between a shelf document and an actionable plan.

- Executive summary with risk profile – A clear overview of where your risks sit, the top priorities, and any compliance gaps.

- Traffic-light action list – Items grouped by High, Medium, and Low, with justifications and photos. High items should be immediately actionable by your electrical services team.

- Costed recommendations and staging – Budget ranges, suggested sequencing, and any dependencies help you plan works across financial years.

- Compliance mapping – Findings mapped to relevant standards and regulatory duties so you can answer insurer, regulator, or board queries with confidence.

- Drawing and labelling updates – Marked-up diagrams or a defined scope to correct documentation, plus a labelling schedule for boards and circuits.

- Maintenance calendar – A suggested cadence for RCD tests, thermography, emergency lighting tests, and periodic board inspections.

The Bottom Line

A professional electrical safety audit gives you clarity and control. It finds hazards early, aligns your site with current requirements, and provides a plan your team can deliver without drama. When paired with dependable electrical services, it improves safety, reduces downtime, and protects your investment. If your site has grown, changed tenants, or simply has gaps in its documentation, schedule an audit and turn compliance into a practical advantage.