Economy controls are meant to be the “easy win” in air conditioning. Use cooler outside air when it helps, reduce mechanical cooling, and keep spaces comfortable with less energy. In the real world, economy control is also one of the quickest ways to create hot-cold swings, drafts, humidity issues, and a building team that turns the feature off because it is too risky.

What Economy Controls Are (and What They Are Not)

Economy controls, sometimes called economiser control, aim to use outside air as a cooling source when conditions allow. Done well, it reduces compressor run time and keeps comfort steady. Done poorly, it becomes a constant tug-of-war between outside air, return air, and mechanical cooling.

A few practical clarifications help set expectations early:

- Economy control is not “free cooling all the time”, it is conditional and should be selective.

- It does not replace ventilation requirements, it works alongside minimum outside air settings.

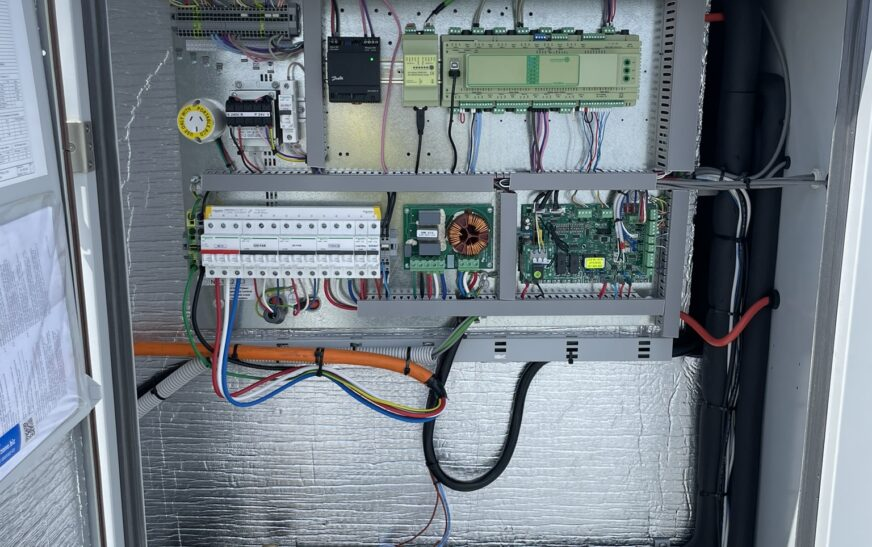

- It is not purely a software feature, it depends heavily on dampers, actuators, and air paths.

- It is not only about temperature, humidity and enthalpy can matter depending on the site.

If your building has frequent complaints during humid or windy days, economy control can still be viable, but it needs tighter enable criteria and better commissioning.

Where Economy Controls Go Wrong in Occupied Buildings

Most comfort problems show up in the same handful of places. They are usually not mysterious faults, they are predictable outcomes of poor setup or untested assumptions.

The most common failure modes include:

- Outside air damper leakage, causing unintended cooling or heating

- Stuck, reversed, or mis-sized actuators that do not follow the command signal

- Incorrect minimum outside air position, leading to over-ventilation and drafts

- Unreliable outside air temperature sensing, especially if the sensor is sun-struck

- No humidity consideration in climates or seasons where humidity matters

- Control loops that “hunt”, with dampers and compressors fighting each other

- Poor changeover logic, with rapid switching between economy and mechanical cooling

- Commissioning done in mild weather only, then failing on the first real heat load day

In busy facilities, like gyms with peak loads and constant door openings, these faults get amplified. Staff notice discomfort quickly and the system gets overridden, which usually makes behaviour even less predictable.

Dampers and Air Paths: The Physical Side You Cannot “Program Around”

Economy control is a damper control problem before it is a controls platform problem. If the dampers leak, bind, or never reach commanded positions, comfort will drift and the controller will keep chasing a moving target.

Key damper and air path items to verify include:

- Damper blades are intact and rigid, aluminium blades are common and durable, but seals still matter

- Louvres and screens are not clogged, bent, or restricting airflow

- Actuator linkage is tight, with no slop that creates dead zones

- Damper closes against a proper stop, not against a twisted frame

- Relief air is handled correctly, so the building does not pressurise or depressurise unpredictably

- Intake locations do not pull in hot exhaust air, kitchen discharge, or vehicle fumes

It is normal to see aluminium components in intake assemblies and dampers, especially where corrosion resistance and weight matter. Aluminium does not guarantee good performance on its own, but it tends to hold up well when the damper is properly installed and sealed.

Sensors and Enable Criteria: Accuracy Beats Ambition

Economy control is only as smart as the data it uses. If outside air temperature is wrong, the system will make the wrong decision, even if the logic is perfectly written. If humidity is relevant and ignored, the system can bring in “cool” air that actually makes the space feel worse.

A practical sensor and criteria setup usually focuses on:

- Outside air temperature sensor placement, shaded and away from heat soak

- Return air temperature validation, because it is often used as a comparison point

- Mixed air temperature monitoring, to confirm the damper sequence produces expected results

- Optional humidity or enthalpy sensing where humidity-driven discomfort is common

- Clear enable thresholds, with deadbands to avoid short cycling between modes

- Lockouts for extreme conditions (smoke events, very high humidity, extreme heat)

The temptation is to make economy control “aggressive” to chase savings. In occupied buildings, stability matters more. A slightly conservative economy enable band often produces fewer complaints and more total usable hours over a year because the system is not constantly disabled by operators.

Key Takeaways

Economy controls can deliver real benefits, but only when the physical dampers, sensors, and logic are treated as a single system. Stability comes from discipline, not clever settings. When the setup, commissioning, and handover are done well, economy control stops being a risky feature and becomes a reliable part of how the building keeps comfort steady.